How to overcome the barriers of switching vehicle fleets to electric

With the UK Government banning the sale of new diesel and petrol cars and vans by 2030 and HGVs by 2040, the transition to alternative-fuelled vehicles is inevitable. Whilst many large fleet operators are developing an early strategy, the decision to move from internal combustion engines (ICE) to electric vehicles (EV) requires careful consideration.

For some it may seem like a no-brainer, but for many fleet operators the decision to switch to electric is charged with uncertainty. The five main barriers to electrification are…

01.

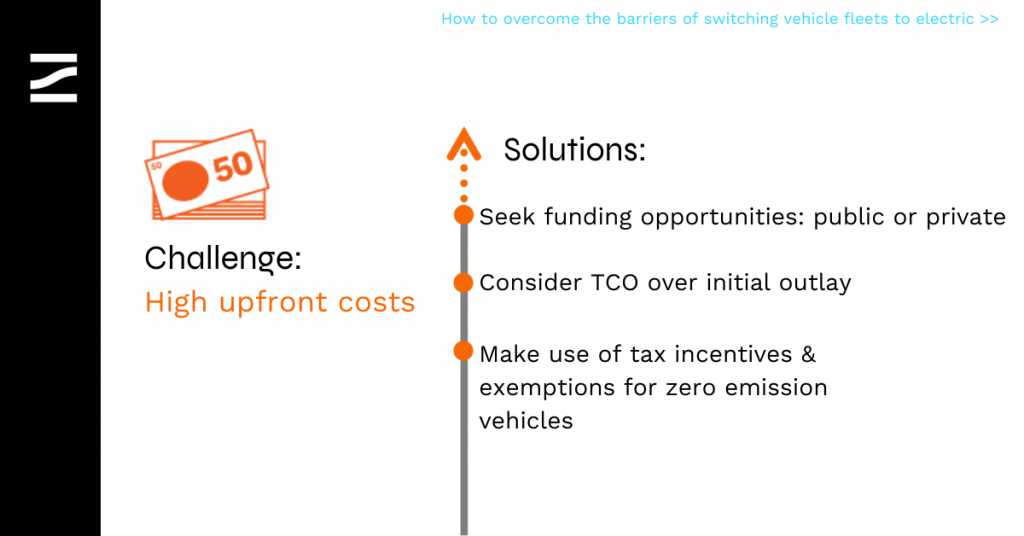

High upfront costs

The capital cost for new (commercial) EVs is still relatively high when compared to traditional ICE models. This is primarily due to the significant cost of the battery packs; their raw material extraction and manufacture. Encouragingly, lithium-ion batteries have reduced in price by c80% since 2013 (BloombergNEF) and further reductions are projected between 2024-2026 to bring the cost of EVs on par with ICE vehicles.

But with the urgency of the climate crisis and corresponding legislation, how can businesses overcome this barrier in the immediate term?

- Many public funds have been made available since 2021, offering partnership, match-funding and more. These can reduce initial capital expenditure (CAPEX) and maximise business opportunity. Read our bus sector funding guide here

- Seek private finance options to spread costs for infrastructure, battery, battery replacement and vehicle across the life of the contract (10-15 years). This a cornerstone of our offering at Zenobē – learn more here

- Look at the Total Cost of Ownership (TCO) not just the initial outlay. EVs have the potential to lower fuel costs by 2-3 times and their maintenance can be 70% less than ICE equivalents

– Make use of tax incentives and exemptions from congestion and ULEZ charges, which are likely to increase and cover more regions of the UK.

02.

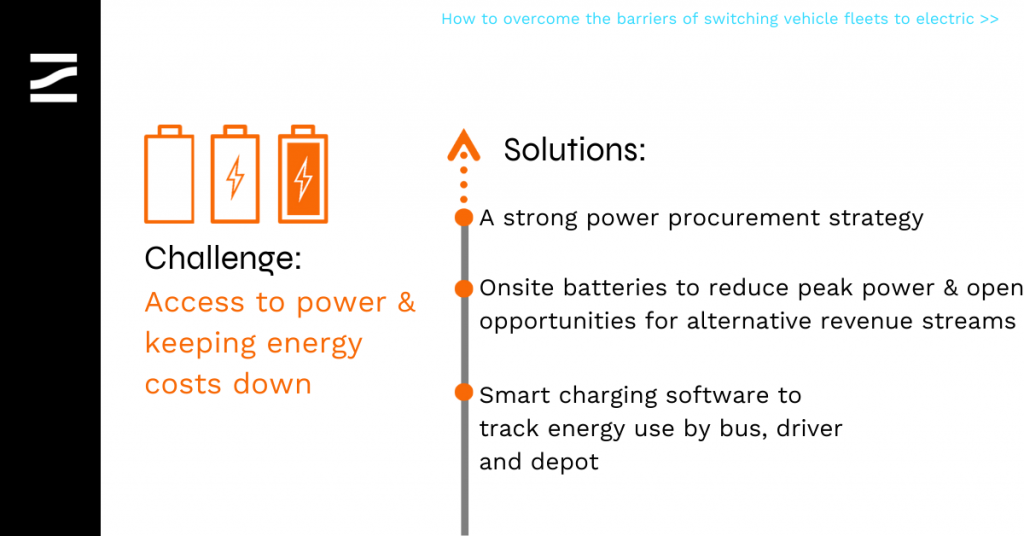

Access to power & keeping energy costs down

Often a depot won’t have access to sufficient power for running an EV fleet and will inevitably need to upgrade their connection to the electricity grid. Arranging a higher power grid connection is often expensive and time consuming. This alongside concerns about running costs and the risk of exceeding local power constraints can deter operators from making the switch.

With the correct power procurement strategy and use of smart charging software these barriers can be overcome.

The right power procurement strategy can:

- Implement onsite batteries to boost supply at peak times and minimise peak power charges; a benefit to local power capacity too

- Use power purchase agreements (PPA) to limit uncertainty around supply and lower costs with connection agreements like a timed connection

- Open opportunities for alternative revenue streams, such as services sold back to the grid or third-party leasing

Smart charging software (such as our own) can be used to track energy use by bus, driver and depot, and:

- Manage the root causes of inefficient driving and incentivise improved driver performance

- Provide energy usage analysis and identify opportunities for reduction

Build an efficient and cost-effective charging strategy

By thoroughly assessing and understanding a fleet’s power requirements, the whole operation can be optimised.

03.

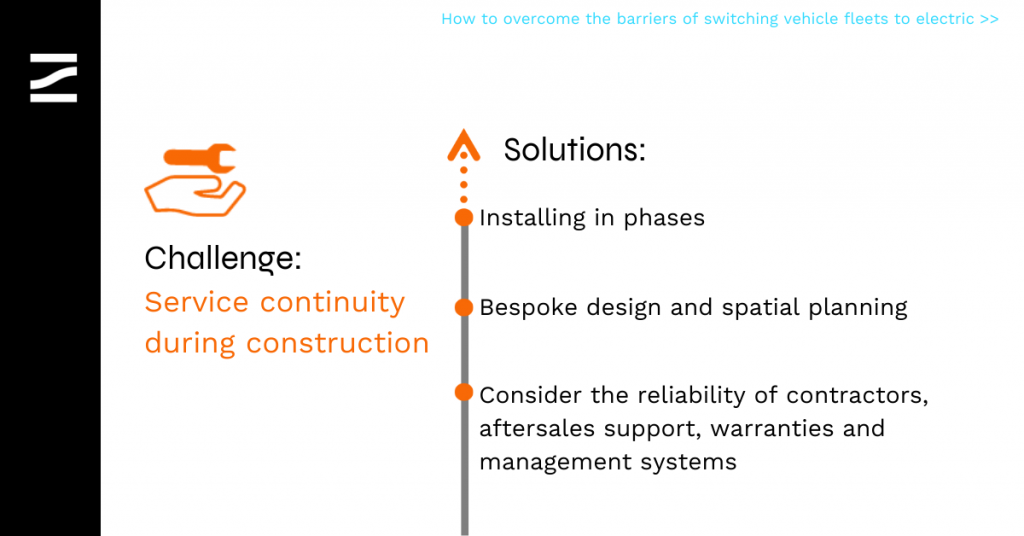

Service continuity during construction

The main challenge here is that EVs require significant building work and electrical infrastructure to be installed. All while the fleet operator continues to deliver services. The fear is that the installation might disrupt existing operations, take too long or be too expensive.

With a proper planning process, these fears don’t have to become a reality.

- Installing in phases can allow normal operations to continue in one area whilst work is completed elsewhere

- Bespoke design and spatial planning can create new parking layouts whilst being sensitive to existing operations

- Working with tried and trusted organisations can ensure business resilience. – Consider: reliable contractors, aftersales support, warranties and management systems

04.

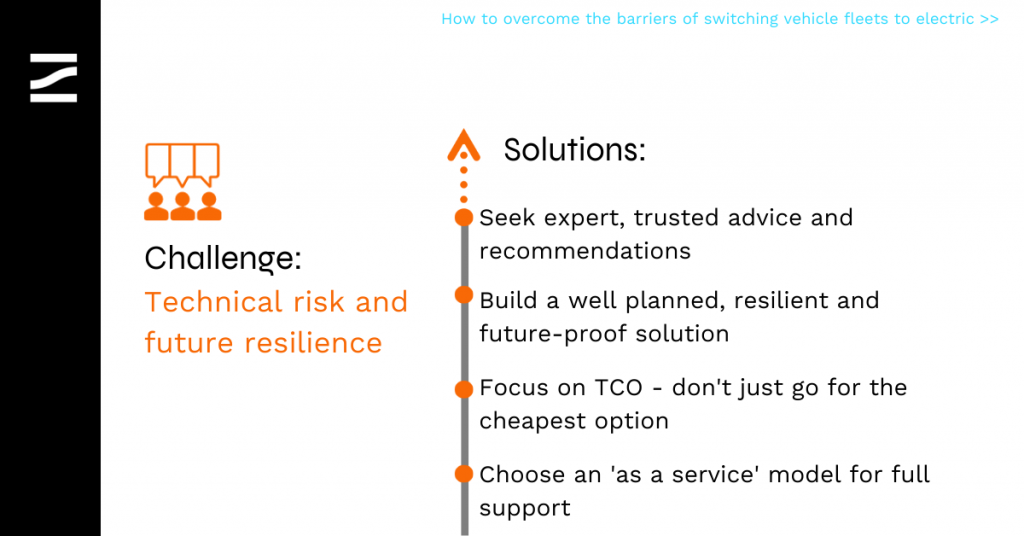

Technical risk and future resilience

EVs and the associated infrastructure are unfamiliar ground for most operators. As a result, the associated technical and operational risks create concerns about business continuity and future resilience.

Operators need the assurance that the new technology will meet and support their needs both now and in the future. With the right choices this can be achieved:

- Seek expert, trusted advice and recommendations from suppliers that have proven experience in the sector.

- Ensure the correct planning, installation and maintenance are adhered to so that electrical infrastructure, chargers and buses are resilient and regret costs are avoided.

- Implement the correct back-office management so issues can be detected and resolved quickly and often remotely, ensuring strong uptime performance.

- Remember that TCO and return on investment (ROI) are achieved over the longer term so don’t just focus on price: consider balancing quality of equipment, reliable support and performance.

- Choose an ‘as a service’ model: you will have peace of mind that issues are taken responsibility for and fixed throughout the lifetime of the contract.

- For example, our Operations team provide support 24/7, 365 days a year, learn more here

05.

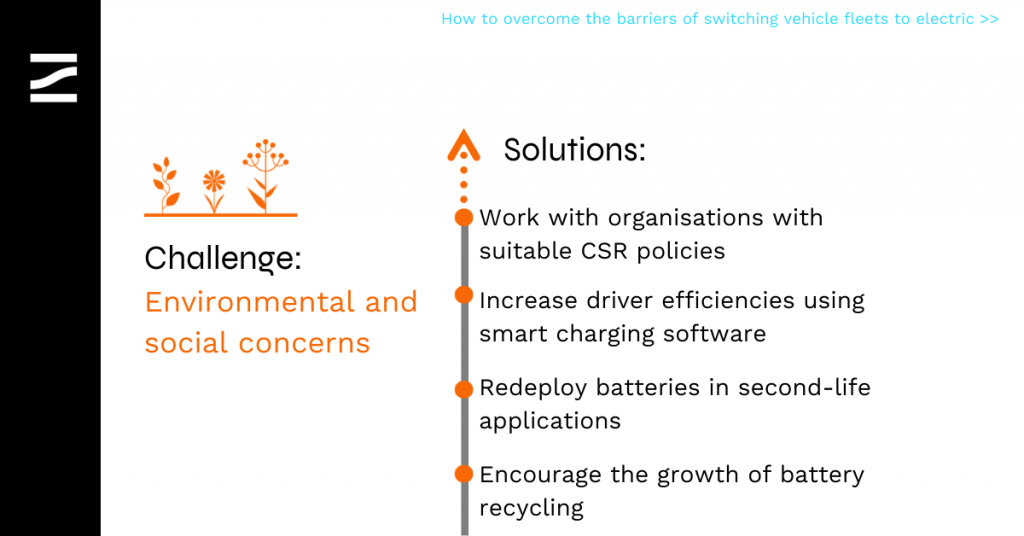

Environmental and social concerns

An average e-bus battery needs replacing every 7 years, raising questions about precious mineral extraction and material waste, carbon emissions as well as the social implications of these activities.

But with carbon emissions associated with battery production being far outweighed by those saved during use (averaging a ratio of 1 tonne emitted: 20 tonnes saved) they’re imperative for our transition to clean transport, energy and air.

By promoting a responsible, circular economy for batteries, we can still see them in a positive light:

Inefficiencies in driver behaviour and charging strategy can be identified through smart charging software to improve battery performance and lengthen its usable life

Batteries that are no longer fit to power EVs can power events and film sets or be redeployed as onsite batteries, with the added benefit of reducing initial cost. We’ve done this for Aertssen and Extreme E

Many organisations (like ourselves) are now committed to ensuring they do not drive human rights abuses through their supply chains nor purchase batteries containing conflict minerals. Read our CSR policy here

Recycling of batteries is a solution which continues to grow alongside demand for batteries, looking to reach a more economically efficient process as soon as possible.

At Zenobē, we recognise the importance of these impacts that’s why we offer ESG reporting on air pollution and carbon emissions savings on our projects. Our end-to-end fleet electrification solution allows fleet operators to make the switch to electric environmentally and financially sustainable.