Electric or Hydrogen: What’s the best option for fleet operators?

Electric or hydrogen? For fleet operators looking to eliminate their emissions and escape skyrocketing diesel prices, the technicalities of low-carbon technologies can be confusing.

We set out to answer three key questions:

- How compatible with net zero are electric and hydrogen fleets?

- How efficiently – or wastefully – do electric and hydrogen road transport systems use energy?

- What does all this mean for operating costs?

We concluded while hydrogen has some essential applications in getting us to net zero, electrification is the most energy-efficient and cost-effective choice for fleet operators. Read on to learn more.

01.

Net Zero Compatibility

Electric

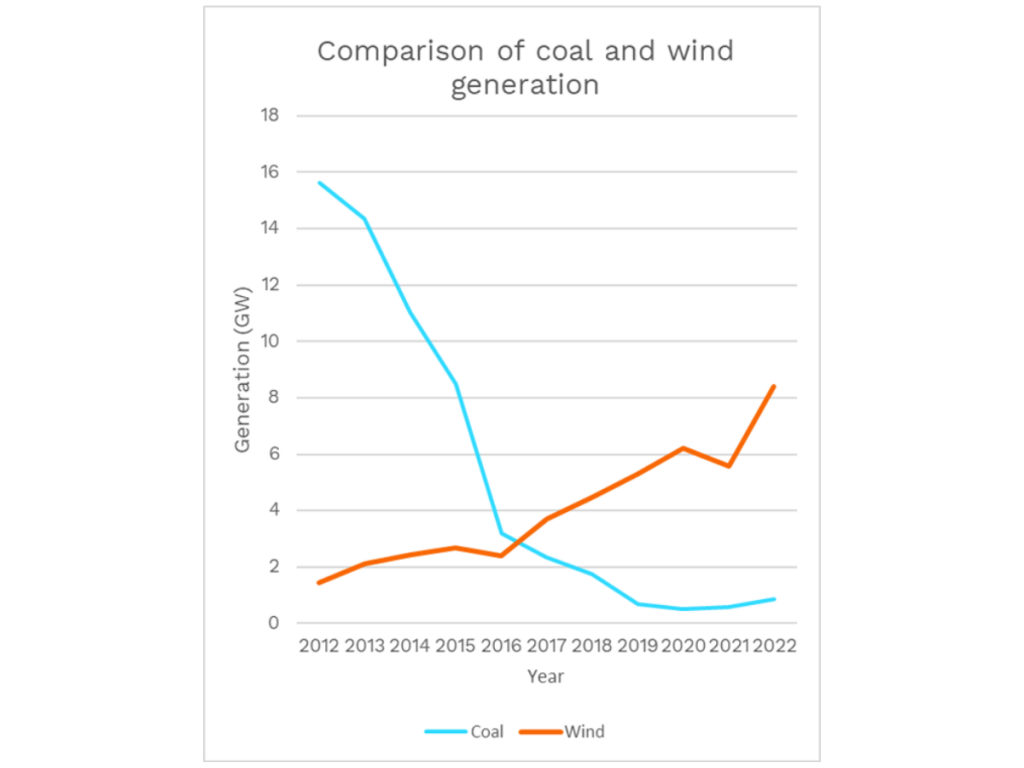

Electric fleets are charged from the grid (unless a depot is supplied with power through a Private Purchase Agreement). The carbon intensity of the UK grid depends on the average carbon intensity of the energy generation mix. This has been rapidly decreasing since 2012, with the adoption of renewables and closure of coal-fired power stations (see figure one).[i]

Figure One: Wind has increased its share of the GB generation mix as coal has plummeted. Yearly Average GB Energy Mix 2012-2022. See https://grid.iamkate.com/ As of 22 March 2022, the monthly average GB generation profile was:

- 32% renewables (wind and solar)

- 34% fossil fuels (mostly fossil gas and a small amount of coal)

- 26% other generation (mostly nuclear and biomass)

- 8% interconnectors (i.e., submarine cables that import electricity from international markets)[ii]

That renewables figure is only going to grow. The UK is advancing towards its goal of decarbonising the electricity system by 2035 with British wind capacity increasing from to 24GW between 2010 and 2019 (1GW is enough to power around 750,000 homes). The recent ScotWind auction saw bidders awarded a whopping 25GW of new wind capacity. Moreover, the Government recently moved to accelerate the uptake of new wind generation, declaring that the auctions through which the UK awards renewable generation contracts will now take place every year, rather than every two years. Hydrogen The UK’s hydrogen economy is in its early stages. In August 2021, the Government released its Hydrogen Strategy, which sets out a plan for achieving 5GW of hydrogen production in the UK by 2030. The Strategy also explores what roles hydrogen might play in decarbonising heavy industry, domestic heating, and certain kinds of transport. So, what are hydrogen’s decarbonisation credentials, how efficient is it as a road transport fuel, and how fast can we expect this technology to scale? There are three types of hydrogen: grey, blue and green. Grey and blue hydrogen are made out of fossil gas – a hydrocarbon, which is split into hydrogen and carbon.

- With grey hydrogen, the carbon is released into the atmosphere, contributing to global warming and certainly not supporting net zero initiatives.

- With blue hydrogen, the carbon is captured and stored – in theory. In practice, blue hydrogen cannot be defined as a zero-carbon technology.

This is because of two factors. Firstly, fossil fuel supply chains have high upstream emissions: they currently release up to 154 million tonnes of methane into the atmosphere every year. Secondly, carbon capture technologies have poor efficiency: the ‘best’ carbon capture rate at an operational blue hydrogen facility is 43%. Happily, there is a fossil-fuel free alternative: green hydrogen. Green hydrogen, which is yet to be adopted at scale, is made through a process called electrolysis, in which water (H2O) is split into hydrogen and oxygen (H2 and O). This process requires electricity. If the electricity comes from renewable sources, the hydrogen is classified as green. As green hydrogen is compatible with net zero, it’s the type of hydrogen we focus on for the rest of the article.

02.

Energy Efficiency

‘Round trip efficiency’ is how much energy a device puts to effective use. For example, a diesel engine might have a 40% round trip efficiency. This means 40% of the energy from the diesel drives the engine, while 60% is lost as heat and sound.

The higher a vehicle’s round trip efficiency, the less energy you need to fuel it.

Electric

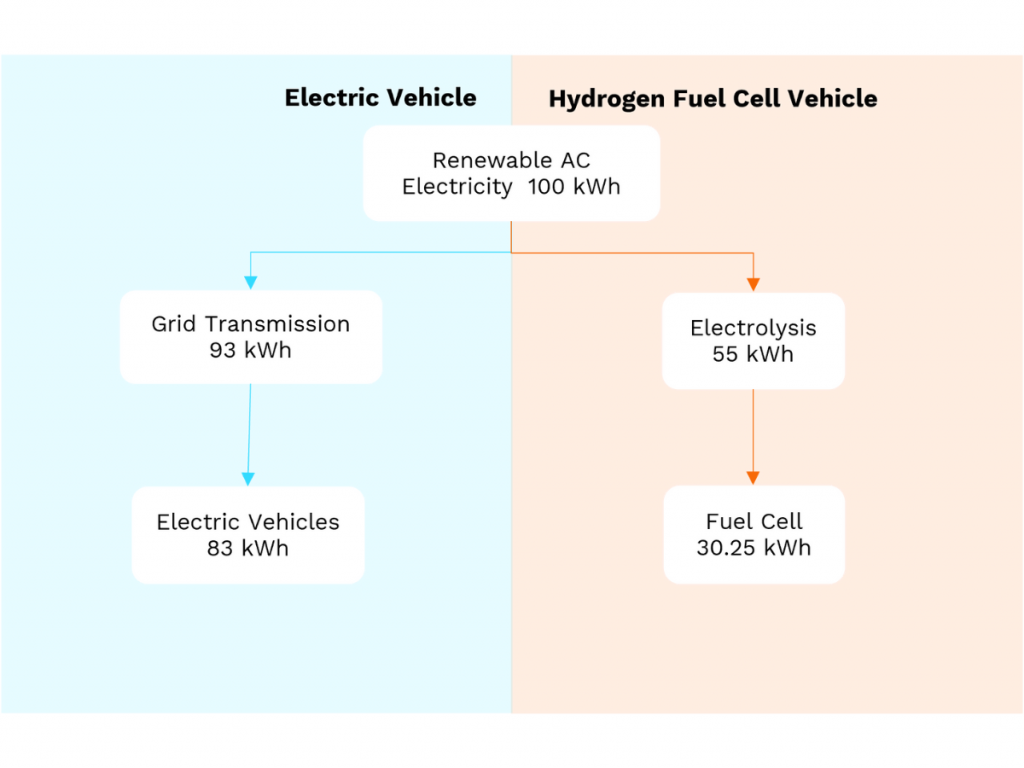

Lithium-ion batteries have a very high round trip efficiency – close to 90%. But the process of delivering electricity from generators, through the grid, and into batteries also involves some energy loss. The total efficiency of this process works out at around 83%.

Hydrogen

There are many stages in the green hydrogen production process: converting AC into DC power, using that power to split water apart into hydrogen and oxygen, compressing the hydrogen so it can be stored, transporting the hydrogen to where it is needed, and finally converting that hydrogen back into electricity in a fuel cell engine. Each of these stages is an opportunity for energy loss. As a result, green hydrogen road transport systems have a very low round trip efficiency: around 30%.

03.

The upshot: cost effectiveness

In short: battery-powered transport systems use renewable electricity almost three times more efficiently than green hydrogen fuel cells. This means that if the UK transport sector decided to decarbonise by switching fully to green hydrogen, we would need three times as much renewable energy as we would with a fully battery-powered transport system.

For fleet operators, the different efficiencies of battery and hydrogen technologies will be reflected in running costs. In other words, the price of hydrogen per vehicle mile will be higher than battery electric, unless or until technologies improve. There will be some exceptions to this rule: for example, operators who happen to work close to ‘hydrogen transport hubs’ will benefit from savings from shared infrastructure and logistics. But battery electric technology is scalable at much lower cost, and with much higher efficiencies.

Green hydrogen may be key to getting us to net zero: decarbonising heavy industry, decarbonising air travel, and powering localised hydrogen ‘ecosystems’. But for the transport sector, it is clear that battery electric will be the first technology to reach scale.